Características

•Adopt the high-efficiency three-dimensional flow semi-open impeller with the professional aerodynamic and structural design to realize the optimal aerodynamics performances. The impeller materials shall select the wrought aluminum for aviation and stainless steel and shall be manufactured through the milling of simultaneous machining center so as to guarantee the precision of impeller machining and meet the design requirements.

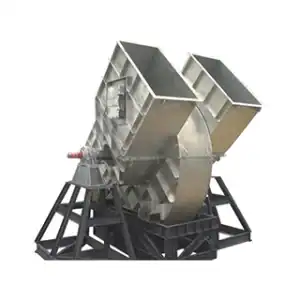

•The single-stage high-speed centrifugal blower is composed of a blower body, shaft coupling, motor, lubrication oil station, control cabinet, filter, silencer, expansion joint, release valve, releasing silencer, check valve, electric butterfly valve, noise insulation cover, control panel, and instruments and apparatus, etc.

Parámetros

| Type | ( m3/min ) | ( Kpa ) | ↋ | A1(mm) | A2(mm) | H1(mm) | H2(mm) | L(mm) | L1(mm) | D1(mm) | D2(mm) | Power(KW) | Weight(KG) |

| D50 | 50-80 | 30-120 | 1.3-2.2 | 1300 | 480 | 1200 | 800 | 2200 | 1800 | 200 | 200 | 75-200 | 3000 |

| D80 | 80-100 | 30-130 | 1.3-2.3 | 1300 | 520 | 1500 | 960 | 2600 | 2100 | 250 | 280 | 75-250 | 3200 |

| D100 | 100-150 | 30-160 | 1.3-2.6 | 1300 | 580 | 1500 | 960 | 2600 | 2100 | 280 | 280 | 75-450 | 3500 |

| D150 | 150-200 | 30-160 | 1.3-2.6 | 1300 | 580 | 1500 | 960 | 2600 | 2100 | 280 | 320 | 110-560 | 4000 |

| D200 | 200-250 | 30-180 | 1.3-2.8 | 1300 | 660 | 1500 | 1010 | 2600 | 2100 | 320 | 320 | 132-800 | 4500 |

| D250 | 250-300 | 30-200 | 1.3-3 | 1400 | 660 | 1600 | 1010 | 3200 | 2650 | 320 | 350 | 160-1000 | 5500 |

| D300 | 300-350 | 30-200 | 1.3-3 | 1400 | 750 | 1600 | 1010 | 3200 | 2650 | 400 | 350 | 200-1200 | 5600 |

| D350 | 350-400 | 30-200 | 1.3-3 | 1400 | 750 | 1600 | 1010 | 3200 | 2650 | 400 | 400 | 250-1400 | 5600 |

| D400 | 400-450 | 30-160 | 1.3-2.6 | 1550 | 860 | 1700 | 1010 | 3600 | 3200 | 450 | 400 | 280-1250 | 5800 |

| D450 | 450-500 | 30-160 | 1.3-2.6 | 1700 | 860 | 2200 | 1400 | 3600 | 3200 | 500 | 450 | 315-1400 | 6200 |

| D500 | 500-600 | 30-160 | 1.3-2.6 | 1700 | 860 | 2200 | 1400 | 3600 | 3200 | 500 | 450 | 335-1800 | 7000 |

| D600 | 600-800 | 30-160 | 1.3-2.6 | 1800 | 920 | 2200 | 1400 | 3600 | 3200 | 600 | 450 | 400-2240 | 7500 |

| D800 | 800-900 | 30-160 | 1.3-2.6 | 2200 | 1020 | 2200 | 1400 | 4500 | 3500 | 600 | 500 | 560-2500 | 8000 |

| D900 | 900-1000 | 30-140 | 1.3-2.4 | 2200 | 1100 | 2300 | 1600 | 4500 | 3500 | 600 | 600 | 630-2500 | 9000 |

| D1000 | 1000-1100 | 30-120 | 1.3-2.4 | 2200 | 1200 | 2300 | 1600 | 5000 | 3800 | 600 | 600 | 710-2500 | 10000 |